BTOB RAIL MAG 2023

Contributing to the future

with Smart-E-Power®

Making a positive contribution to climate change through minimal power loss, high energy efficiency, less CO2 production, long product life expectancy and minimal maintenance. These are the strengths of Bächli AG.

Bächli is a Swiss tech company that specialises in the development and production of electrotechnical components. The company’s range of products comprises highly specialised transformers, chokes and wound products of all kinds that are used in differing industrial products.

The company is based in Switzerland has a proud history of successfully partnering with international industrial companies that spans over 70 years.

Modern rail-based transportation systems focus on safety, efficiency and a good environmental balance. Efficient electrotechnical components form the basis for the reliable control of energy. The solutions developed by Bächli draws on the company’s long-standing experience. The wide range of tried and trusted products – combined with the innovative capacity to develop new solutions – make Bächli the leader in technology for chokes and transformers used in rail technology.

One of the major challenges is to design the right transformer for a specific application. Legislation, technical standards, electrical and mechanical requirements, design preferences, efficiency, space requirements, weight, etc. are just some of the many considerations needed to find the optimal solution. Thus, the prioritisation of these criterias is an important part of the design process. The weighting of the individual parameters strongly influences the product design and is therefore a fundamental decision Bächli AG is the expert when it comes to developing these solutions for your needs (energy-efficient, compact, light, cool, inexpensive). We would like to emphasize that energy efficiency and cost-effectiveness are by no means mutually exclusive!

Utilisation of energy-efficient winding goods

The efficiency of a transformer can be influenced by various aspects, such as the choice of material, the method of the calculation/simulation or the accuracy of the manufacture. In general, inductive components have a high efficiency. Nevertheless, there are still design options to increase the energy efficiency of a product.Our engineers are very competent in this field and help you to design the product optimally according to a wide variety of criteria. But also in a very sustainable and resource-saving way.

Bächli has its own Smart-E-Power® product line for this purpose. It stands for the highest possible efficiency. These products are characterised by the smallest possible efficiency losses. Consequently, operating costs are reduced to a minimum and CO2 emissions are lowered substantially.

We would like to show you the benefits of the Smart-E-Power® product line with an example. In the following, the standard variant and the Smart-E-Power series are compared using a 70kV auxiliary converter transformer. The basic condition for both variants was limited space capacity with limited heat generation.

An insight into the product portfolio of Bächli AG in the field of mobility:

- Reactors and transformers for rolling stock

- Mains insulating transformers protection category 2 for railway networks

- Point heating transformers

- Bidirectional 16.7 Hz/50 Hz frequency converters

- DC circuit supply and battery charging

- Long distance AC and DC transmission for signalling and power supply along railway tracks

- EMC filter technology

- Variable multi-voltage AC and DC rail test systems with 50 Hz and 16.7 Hz generation for locomotives, railcars and passenger coaches

Table 1: Comparison of the standard and Smart-E-Power variant in case of a auxiliary converter transformer

No-load losses occur in the transformer even if no electrical energy is drawn from the connected loads. It is said that the transformer runs or works in no-load operation. The no-load losses are effective 24 hours a day, 365 days a year, and only 1W less results in a saving of approx 8.7kWh.

The table clearly shows that the Smart-E-Power® variant has significantly lower no-load losses. As a result, there are 40% lower no-load losses per year, This means that much less energy is consumed per year by the Smart-E-Power® variant.

It is observable, that the efficiency of the Smart-E-Power® products has one percent higher efficiency than the standard variant. Hence, there are less energy losses, since in total the standard product generates approx. 3’300 kWh more energy losses per year. Since the lower energy demand means that the annual energy costs are lower. Based on the Swiss energy price of CHF 0.12 per kWh, you can save CHF 400 per year when using the Smart-E-Power product. Due to the high-quality materials in the Smart-E-Power range, the load on the component is lower.

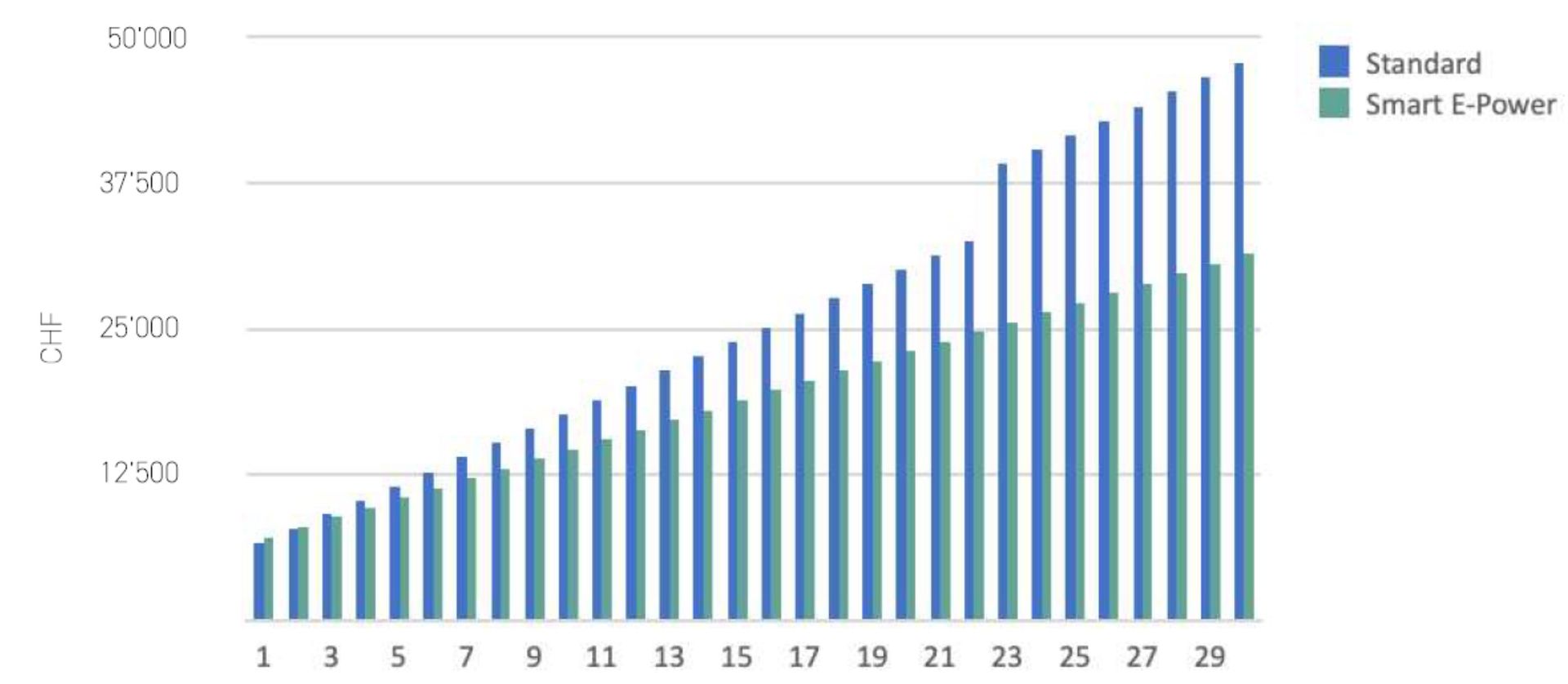

This significantly increases the service life. In our example case, the service life can be doubled. The sustainable transformer operates on average for more than 40 years. Added up over 30 years, this results in a cost saving of CHF 25’080 for the Smart-E-Power® product. In addition, the life cycle is twice as long. Both result in a far more attractive life cost calculation than with the standard product.

As you can see in the following graph, the Smart-E-Power® product already shows a positive cost balance after the third year. The somewhat higher procurement costs of the Smart-E-Power® product due to the use of high-quality materials pay for themselves after a short time.

Since the life cycle of the standard product is theoretically much shorter than that of an energy-efficient product, it must also be replaced sooner. This means, therefore, that after 22 years we have included the procurement of a new auxiliary power transformer. The disposal costs of the products were not included in this calculation.

CO2 savings

The CO2 equivalent provides information on the amount of emission gases produced during the production of energy. According to IWR/2013, one kilowatt hour of electricity (1 kWh) in Switzerland, Northern and Western Europe is equivalent to 590g of carbon dioxide. Losses in form of thermal heating occur in all electrical components - including transformers.

Although they have an efficiency of up to > 99% today, the losses of all active transformers in Central and Northern Europe correspond to about 5.7%. The additional energy requirement also means the use of more natural resources, which can lead to higher greenhouse gas emissions and thus damage the climate.

Therefore, better energy efficiency leads to a more sustainable use of natural resources.

As the name suggests, Smart-E-Power® stands for minimum power losses and high energy efficiency, resulting in a reduction of CO2 emissions. The calculated CO2 equivalent of the compact Smart-E-Power® auxiliary converter transformer is 6964 kWh, around 2t less than the compact standard version. The savings correspond to a yearly return flight from Zurich to New York (/co2.myclimate.org).

If a life cycle of 30 years is assumed on average, this results in a possible total savings of 99’930t CO2. To put the savings in to perspective, approximately 13800 hot air balloons can be filled with the CO2 saved.

The opportunity to make your product more sustainable and energy-efficient is not at odds with economic efficiency. Take advantage of this opportunity and work out the optimum variant of the Smart-E-Power® product for you together with our engineers. We will be glad to be your competent partner from the development to the installation of the product.

It is important to us to make an active contribution to sustainability. We would be happy to support you in this process - let us work together to drive forward an implementation and application of sustainability for the future.

Calculations were made using the example of the 70kV auxiliary converter in the standard output in the Smart-E-Power® variant.

In the graph, it can be seen that already from year three, the costs of the Smart-E-Power product are lower than those of the standard solution. From this, it can be concluded that the savings in energy and maintenance costs quickly equalize the procurement price.

sustainability calculator on the Bächli AG homepage

On the Bächli AG homepage you will find the sustainability calculator: https://www.baechli.com/nachhaltigkeitsrechner. With the sustainability calculator you can calculate yourself, how much CO2 you can save by using an energy-efficient product. In addition to this, you will be shown the potential savings in electricity costs, which is a very useful topic at the moment.