BTOB RAIL MAG

Some CLEARSY soft-cost range of products focus on light rail and tram

Since its creation in 2001, CLEARSY has been offering more and more innovative solutions for making transport safer, particularly in urban areas. For almost 10 years, CLEARSY has been involved in light rail signaling projects (renovations, extensions, or new lines). As usual, we focus on safety matter, so our main concern is interlocking control via SIL4-certified off-the-shelf PLCs, safety relays and Automatic Train Stop (ATS) system. These lightweight solutions facilitate design, certification, deployment and, of course, maintenance throughout the system’s lifetime, and make it easy to renew.

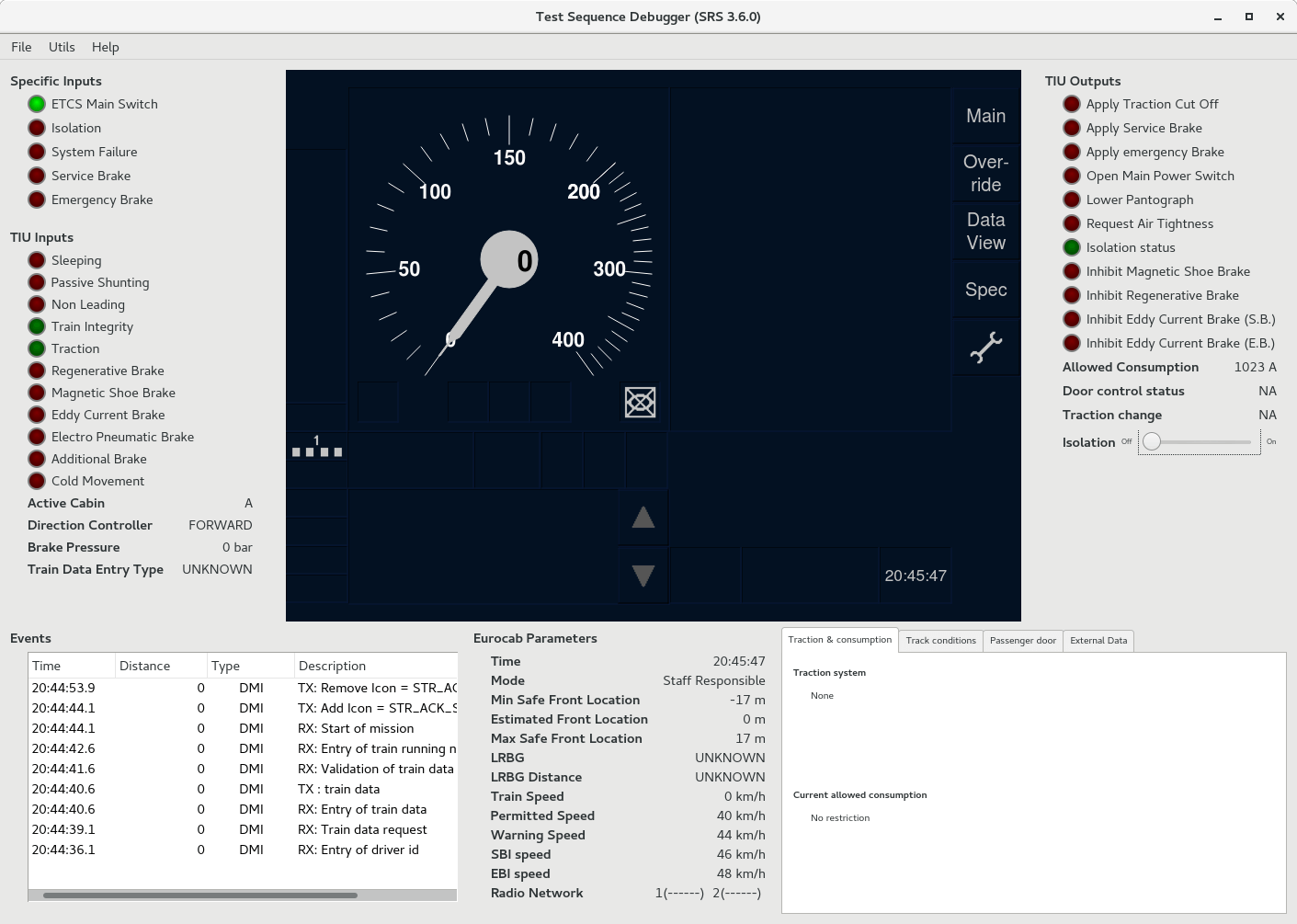

Architecture for safety first

The architecture proposed by CLEARSY is based on several certified equipment

- COTS PLC (Programmable Logic Controller) from HIMA certified SIL4 for all the interlocking logic execution

- RS4 vital relays designed and provided by CLEARSY for interface and logic purposes

- SIL2 ATS system designed and provided by CLEARSY to prevent driver to go through a restrictive signal (red)

This architecture, which can be reused for each project, also enables us to anticipate supply requirements much more effectively, as the only required information to start procurement is the quantity of inputs/outputs and point to protect with ATS.

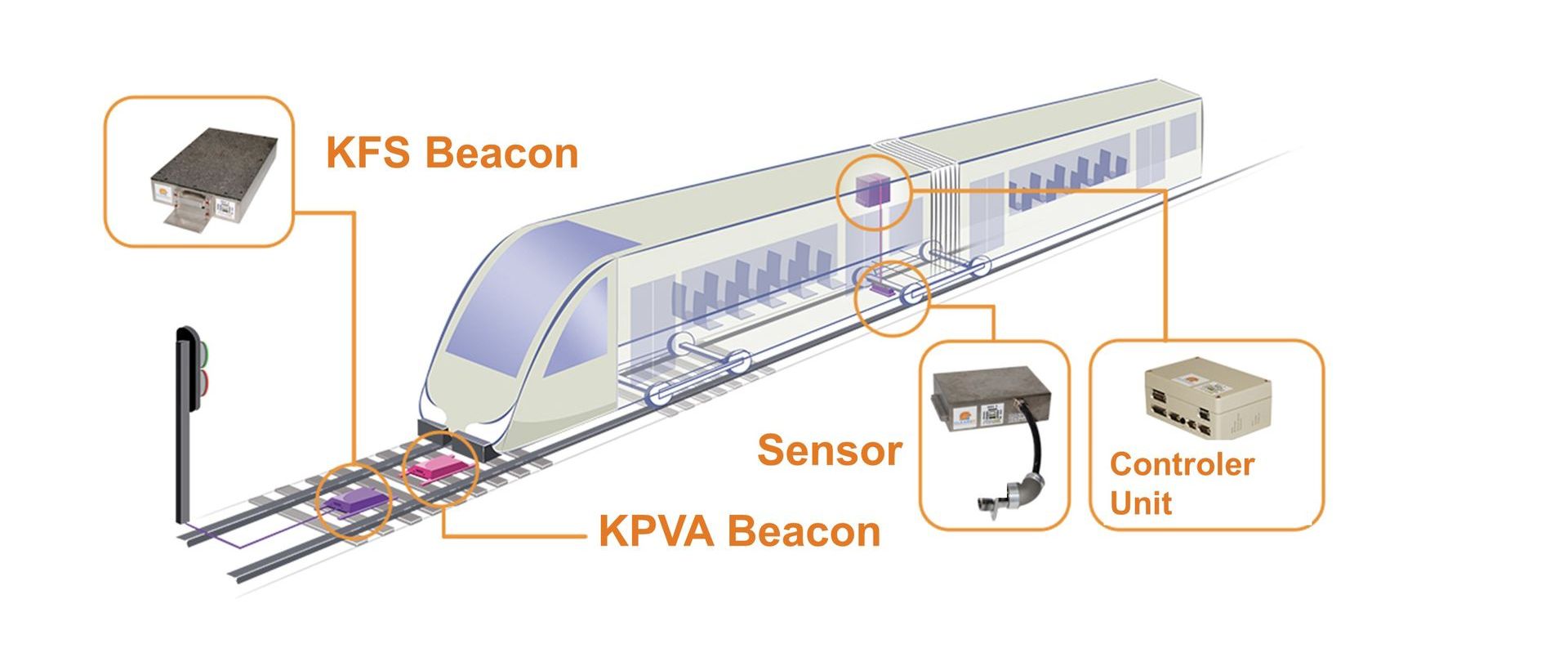

Interlocking logic

As a design office, CLEARSY takes the responsibility to implement the logic correctly in the PLC in accordance with railway standards, in particular CENELEC EN50128. This logic is specified by the signaling schematics and technical drawings provided by the integrator. The entire development and validation process is driven by the CENELEC process because the end goal is to obtain a positive SIL4 evaluation report from an independent safety assessor (ISA) (such as Bureau Veritas or Certifer).

The validation process uses automatic tools developed and qualified by CLEARSY to enhance the efficiency of the process. This “industrialization” of the V cycle activity allows for guaranteed the safety and compliance with the standards but also automates and makes the validation process repeatable

Having a programed logic on a PLC instead of relay-based logic makes it much easier to evolve. . In case of evolution, the only activities required is to implement the changes and replay the automatic tests in the laboratory to validate the modification and ensure the non-regression. Compared to a relay-based architecture, this means that all cabling and deployment elements do not need to be revalidated. As a result, the effort required is reduced, and the execution schedule is kept under control. Potential changes can therefore be made at any time during the development cycle or the life of the project.

RS4 SIL4 relay

The RS4 relay was designed by CLEARSY 10 years ago to simplify the PLC safety interface; currently it is used for various functions in railway industry. Available in a range of references with different contact arrangements and working voltages, more than 15,000 units are in service all around the word. In the interlocking context, the RS4 relay provides the interface with trackside equipment, while guaranteeing an insulation level (2 KVA) and maintaining the SIL4 safety level.

Basically, as this relay is safe there is no need to read back the normally-closed contact. It means that there is no need to use input on the PLC for this reading function. So it not only saves space (in addition to the relay’s small form factor) but it also saves money on each project.

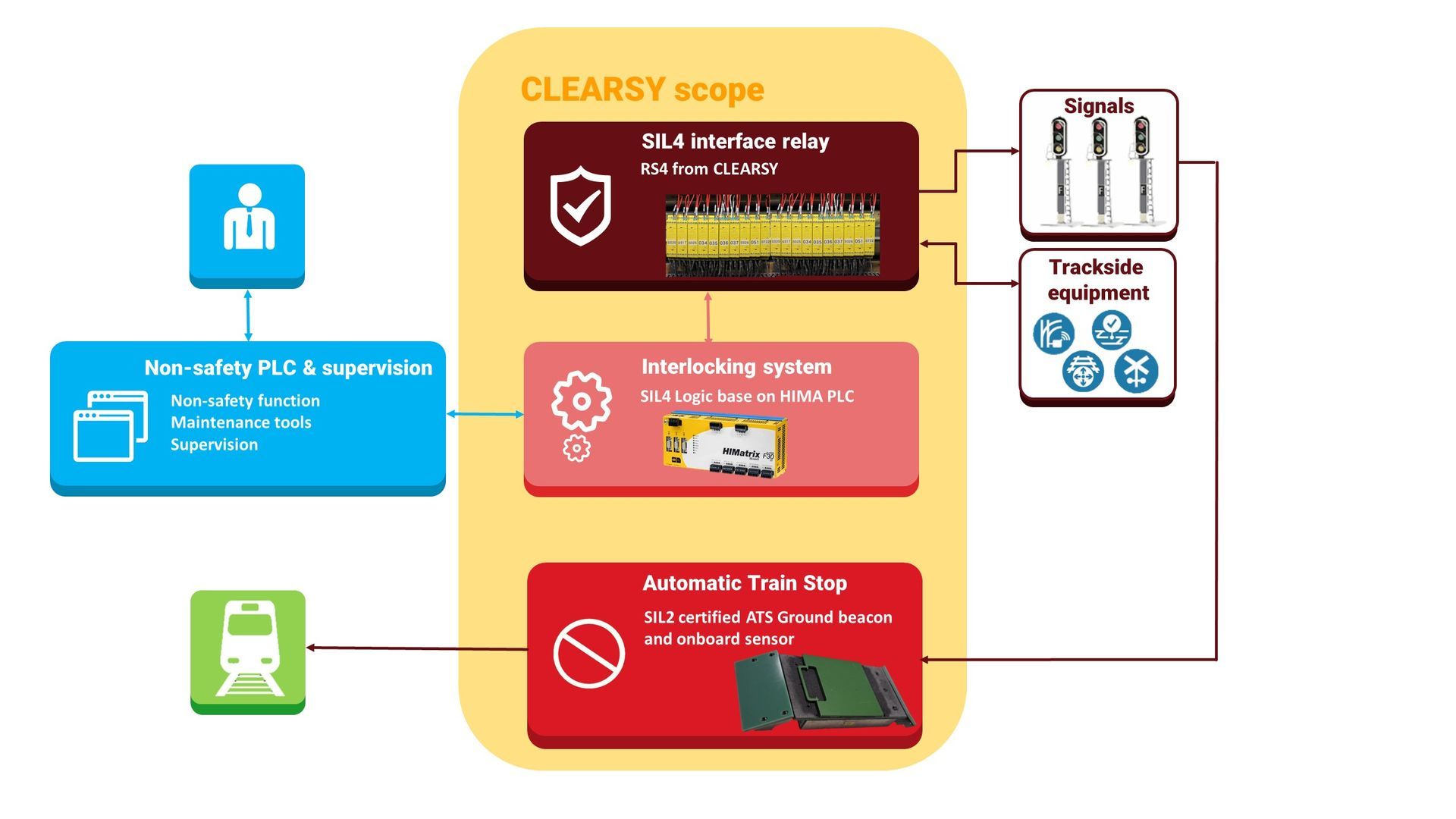

ATS system

Our SIL2 safety system stops the train when a red signal is crossed, thus avoiding the risk of collision on single-track sections.

It is composed of:

- A ground beacon connected to the signal

- An on board control unit, connected to the emergency brake system

- An on board sensor, to detect the status of the ground beacon

This CLEARSY’s automatic train braking system (ATS) doesn’t need train location information (odometer) and doesn’t need any train localization system installation. It’s only necessary to install one beacon connected to the signal. So, CLEARSY’s ATS system is very simple to install and avoids installing a more complex system based on an odometer and a cartography.

All the beacons interact with on-board units through different fields:

- A continuous magnetic field, This field is polarized (Contains a north and a south pole). The system uses this property to detect the direction of the beacon and by default, a stop signal.

- An electromagnetic field, This field is activated simultaneously with the permissive signal in order to allow the train to cross the signal safely, “canceling” the default stop signal.

CLEARSY’s products focus on

light rail and tram

CLEARSY’s experience in this type of project means that we have a highly efficient, industrialized process, with automated test tools, high level of safety certified by ISA, within a reduced and under control cost compared to other solutions.

With the CLEARSY solution, the larger the zone scope (number of routes, track equipment, etc.), the greater the difference in cost and cabinet volume compared with a solution based on relay logic, while reducing site testing time due to an exhaustive factory pre-validation.